|

| |

COTTON GINNING |

|

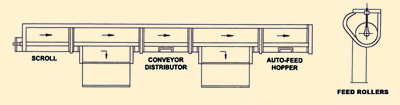

| LINE FEEDER & CONVEYOR DISTRIBUTOR |

| |

|

| FOR SEED-COTTON, COTTON-SEED & COTTON LINT SEED-COTTON HANDLING EQUIPMENT |

| |

-

High capacity 410 mm (16”) auger hanged by heavy-duty anti-friction bearings

-

Trough specially designed for smoother and undisturbed flow of cotton without roping and complete flow into hopper until filled

-

Loose depositing of cotton in hoppers without picking effect for free flow through waiting hoppers/auto-feeders

-

Five door provided on request

|

|

| AUTO-FEED HOPPER |

- To be hanged from conveyor distributor

- Feed rate controlled by actuating feed-rollers as required

|

|

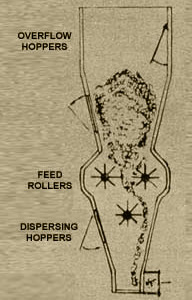

| OVER-FLOW HOPPER |

-

Equipped with feed and dispersing rollers and level switches interlocked with operation of feed rollers and change over valve in pneumatic system

-

Tailor-made to optimize storage capacity of over-flow pen and rate of reclamation to suit plant capacity

|

|

|

|

|

| |

COTTON LINT HANDLING EQUIPMENT |

|

| |

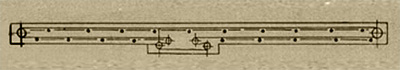

LINT BELT CONVEYOR |

-

Specially designed for carrying cotton-lint. Long belt life and maintenance free operation

-

Available in belt widths 305 mm (12”), 460 mm (18”) and 610 mm (24”)

-

Normally provided with non-troughing idlers, troughing side plates and decking plates throughout to save belting from damage due to undue loading

|

|

| OTHER MEANS OF LINT HANDLING |

LINT FLUE SYSTEM WITH CONDENSER-See NIPHA Pneumatic Handling Systems |

| |

SEED-COTTON HANDLING EQUIPMENT |

|

| |

| Back |